During use, plastic materials experience chemical and physical changes caused by environmental stresses such as sunlight, heat, moisture, pollutants, mechanical stresses, and biological growth. This ‘weathering’ of a material has serious implications for its durability and degradation over time. Using state-of-the-art weathering chambers, we can create conditions that cause samples to undergo accelerated weathering. Samples will be subject to UV to imitate sunlight and water to imitate humidity and rain, causing samples to weather in weeks or months as opposed to years.

It’s critical to have the ability to determine the end-of-life fate of a material when fully assessing its overall measure of sustainability and making recommendations of appropriate uses and methods of disposal. To study how compostable materials degrade during the composting process, the industrial composter will compost materials in aerobic conditions with temperatures up to 80 °C.

The SMI Hub has two permeability instruments, one for measuring the permeability of materials towards humidity and one for measuring the permeability of materials towards gases, specifically oxygen and carbon dioxide. The permeability instruments can test the barrier properties of materials. Useful applications include understanding how protective plastics will be when used for packaging perishable items such as food, beverages, and healthcare products.

Polymer extrusion is a critical step that allows existing polymers to be transformed into more practical and functional shapes such as films and fibres. It can also be used to simulate the conditions experienced by a polymer during reprocessing or recycling, which are often done at high temperatures and can lead to gradual degradation of plastics, reducing their performance. Plastic extruders are also used to prepare recycled plastic waste and/or raw materials after cleaning, sorting and/or blending into filaments suitable for blending into the resin pellet stock used by the plastics industry at large. The SMI Hub has three extruders: a Process 11 (bench-top extruder), a Polylab (blown-film extruder) and a FET (fibre-line extruder) system.

These instruments are used to characterise the thermal properties of materials including:

This can give detailed insight into the stability and behaviour of a material during various stages of its functional lifetime, particularly when that may involve exposure to extreme hot or cold temperatures, as well as understanding whether new material choices will be fit for purpose in existing complex systems.

Understanding the thermal properties of a plastic is also critical. The processing temperature of can greatly affect the way it responds to stress. Knowing how polymers react to temperature changes gives further insight into how plastic packaging is formed and the variances it can have.

The most common thermal analysis techniques are known as differential scanning calorimetry (DSC) and thermogravimetric analysis (TGA). DSC heats and cools samples to give information on phase transitions (e.g., Tm, Tg, Tc) that samples undergo for given temperature profiles. Special attachments to the DSC allow us to study samples that react to UV or visible light (i.e., photocuring). TGA heats/cools samples in a controlled atmosphere and monitors the mass of the sample over time. This measurement provides information about physical phenomena, such as adsorption and desorption; as well as chemical phenomena, including thermal decomposition. When heated, plastics will lose mass in the form of volatile compounds; the TGA in the SMI Hub is outfitted with a mass spectrometer, allowing us to monitor the volatiles released (e.g., residual solvent, decomposition products, etc.).

Assessing the flow behaviour (i.e., viscosity) and mechanical properties of materials is critical to optimising their design, use, and recycling. Our instrumentation can be used to probe, for example, whether a plastic will be able to tolerate the stresses it could be exposed to during its functional lifetime, or whether a more sustainable additive in a cosmetic or cleaning product formulation will provide the flow properties required to ensure product performance. Rheology is also a critical diagnostic tool for producing identical products from batch to batch.

The instruments used for this will be the rheometer and dynamic mechanical analyser (DMA). Rheology characterises the deformation and flow behaviour of materials and is typically used to measure the properties of liquid/gel/oil samples. The DMA measures the mechanical properties of solid samples such as small bars of polymer, polymer films/fibres, solid foams, and stiff gels. It also has the capability to control the sample environment (e.g., humidity, submersion) during analysis.

Light with wavelengths ranging from the ultra-violet (UV) to the infrared (IR) can provide insight on the composition, chemical structure, thickness, and optical properties of materials. Spectroscopic characterisation of materials has countless potential uses in product development, plastic manufacturing, material weathering, and recycling. For example, spectroscopic signals may change during product weathering due to oxidation, or during recycling due to undesirable chemical reactions.

The Fourier-transform infrared spectrometer (FTIR) can give information on the chemical composition of samples, i.e., what types of bonds are present within a molecule. From this, chemical structures of materials can be deduced.

The UV-VIS spectrometer (UV-VIS) measures the absorption/transmission/reflection of light from a sample allowing for the determination of concentration of the sample. UV-VIS measurements also gives information on the electronic structure of samples.

The ellipsometer measures changes in the state of light and is primarily used for characterising thin films, laminated materials, and surface coatings. The ellipsometer measures the thickness and topology of the sample. It can also measure optical constants e.g., refractive index (n) and extinction coefficients (k) as a function of wavelength for dielectric materials. The ellipsometer in the SMI Hub has an extended wavelength range, capable of measuring into the infrared. The reflectometer, or thin film analyser, is a complementary instrument to the ellipsometer that gives information on the thicknesses of single or multi-layer films

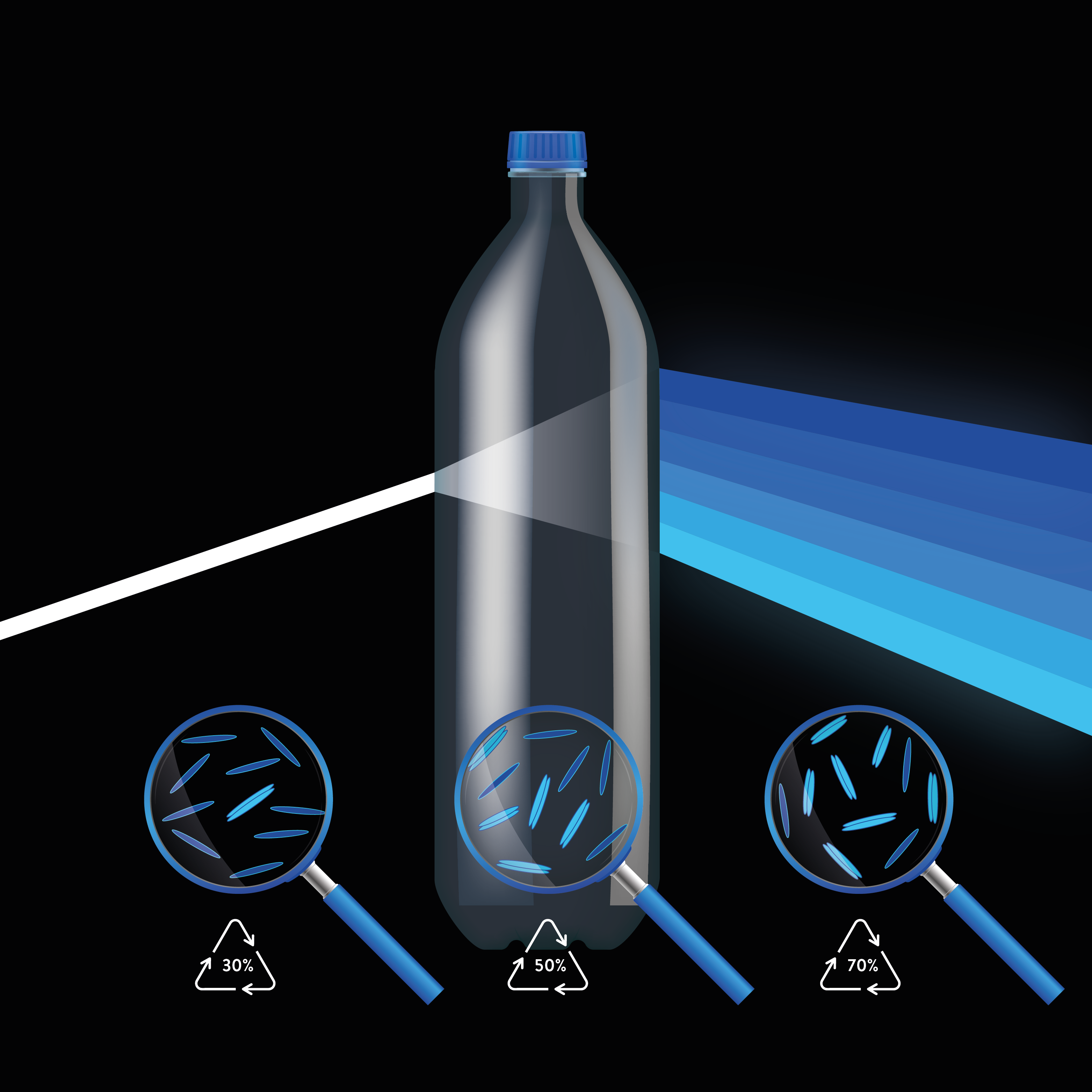

The size of individual plastic molecules dictates the properties of the bulk material, including processability, mechanical strength, and (bio)degradation. Accurate measurements of the average polymer size and its distribution (i.e., size dispersity) are therefore crucial to evaluate batch-to-batch variability as well as overall suitability for the proposed applications of a plastic.

We use size exclusion chromatography (SEC) instruments, which separate a polymer sample into its constituent fractions and performs detailed analysis on each fraction as well as the overall size distribution. This technique requires the sample to be initially dissolved in an appropriate solvent, and the SMI Hub has a range of solvents to choose from. There are several methods by which the size of a polymer is calculated during SEC – including the use of reference samples, light scattering, or viscosity – all of which are available. High-temperature SEC is another variation of this technique that is particularly useful for solvent-resistant materials such as semicrystalline polymers

Dynamic Light Scattering (DLS) instrumentation can be used to gain an understanding of the sizes and size distributions of particles dispersed in liquids. DLS shines a laser through the sample and measures how the light fluctuates due to the interactions between the light of the laser and the particles within the sample. Applications of DLS include understanding particle sizes of polymers, emulsions and colloids. The DLS instrumentation can also be used to measure the electrical charge of particles in a sample (called a zeta potential), which is a key factor regarding the overall stability of the dispersion or solution and impacts the shelf life.

As a chemical process increases in size and complexity, system properties that depend on quantity of matter may change. The surface area to liquid ratio in a reaction vessel is a good example of such a property. Differences between the bench-scale and pilot scale are strongly dependent on the industry and application of interest. The SMI Hub has 5-litre and 20-litre batch reactors with temperature-controlled jackets, in-built stirrers, and atmosphere control. We also have a state-of-the-art modular flow chemistry system. Together, these systems can facilitate the design of full-scale production systems and commercial products, as well as identifying further research objectives, performing quality-control tests and supporting investment decisions.

Hear about the latest news, opinions and activities from the SMI Hub